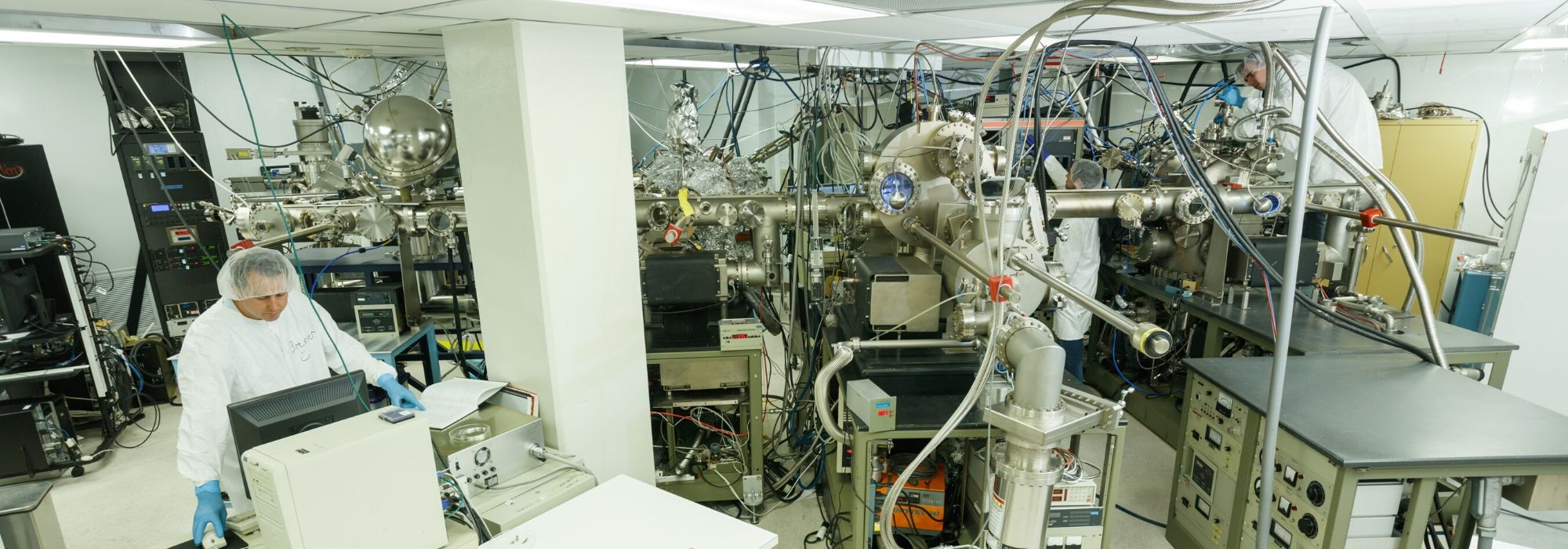

Winter Technologies’ associates have over 100 years of experience in the sanitary, pharmaceutical, biotech, semiconductor, aerospace and instrumentation industries. They know and recognize the special needs of these industries, such as the documentation needed for validation. Many of the processes used today for the manufacturing, polishing and cleaning of tubing and fittings were developed by Winter Technologies’ associates. This experience, plus successful timely innovation, and a willingness to take reasonable risks are key to achieving individual and company growth. Mutual understanding and trust characterize our relationship with customers, suppliers, community and government. We are committed to conducting our business in an ethical and responsible manner.

Winter Technologies sells and services projects, OEMs and MRO business worldwide with strategically located distribution throughout the globe. We provide ASME certified ASME-BPE materials, semiconductor ultra high purity and vacuum tubing, instrumentation, analyzer and commercial tubing needs in 316L, 304L and higher alloys.

Winter Technologies sells and services projects, OEMs and MRO business worldwide with strategically located distribution throughout the globe. We provide ASME certified ASME-BPE materials, semiconductor ultra high purity and vacuum tubing, instrumentation, analyzer and commercial tubing needs in 316L, 304L and higher alloys.

|

|

InSurf

Solving the most demanding surface challenges in Pharma and Bio-Pharma The Corrosion Resistant, Durable, Inert Surface Treatment VIEW CATALOG WinTech Fittings

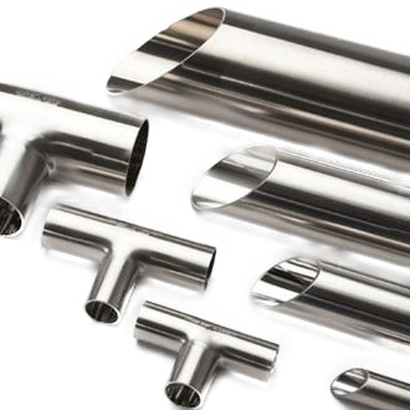

Solving the most demanding surface challenges in Pharma and Bio-Pharma The Corrosion Resistant, Durable, Inert Surface Treatment CLAMP FITTINGS WinTech for-BPE clamp style fittings are easy to assemble and breakdown for process lines and equipment with no axial clearance. WinTech for-BPE clamp fittings made of 316L in 1/4″ through 8″ sizes. Gaskets for clamp fittings are available in several different materials, Buna-N, Teflon®, EPDM, and Viton®. Lightweight and heavy-duty clamps complete the unions and are available from stock. Clamp fittings meet all ASME-BPE requirements and are produced by a certified ASME-BPE manufacturer. WELD FITTINGS WinTech for-BPE weld fittings are used on permanent installations where process piping and equipment can be cleaned in place (CIP) and removal from the system is not required. Weld fittings are offered in nominal tube sizes 1/4″ through 8″ made of 316L. Uniform wall thickness for 1/4″ and 3/8″ is 0.035 (20 ga) 1/2″ through 3″ sizes measure .065 (16 ga), for 4″ size, wall thickness measures .083 (14 ga), 6″ and 8″ .109 (12 ga). WinTech “for-BPE” offers Polished ID and OD Fittings for immediate shipment. Other polished combinations may be ordered. Our weld fittings meet all ASME-BPE requirements and are produced by a certified ASME-BPE manufacturer. These are available from stock. VIEW CATALOG Wintech Tubing

WinTech 10, for-PURE is seamless, welded, welded and drawn and/or mechanically polished, then electropolished to a 7 u-in Ra average

Contact us for more information or if you are ready to place an order.

|