NASVI’s 100,000 sq. ft. warehouse is stocked with 35,000 ready-to-ship valves from the world’s most trusted brands. Plus, decades of helping with sales planning, valve selection and post-sale service makes NASVI your single source for new safety relief valves.

In business since 1975 and a team of factory-trained technicians, they feel confident calling ourselves safety valve experts. Employees are long-timers, and what they know comes in handy when you or your end user has questions about or problems with safety valves.

In business since 1975 and a team of factory-trained technicians, they feel confident calling ourselves safety valve experts. Employees are long-timers, and what they know comes in handy when you or your end user has questions about or problems with safety valves.

|

NEW VALVES

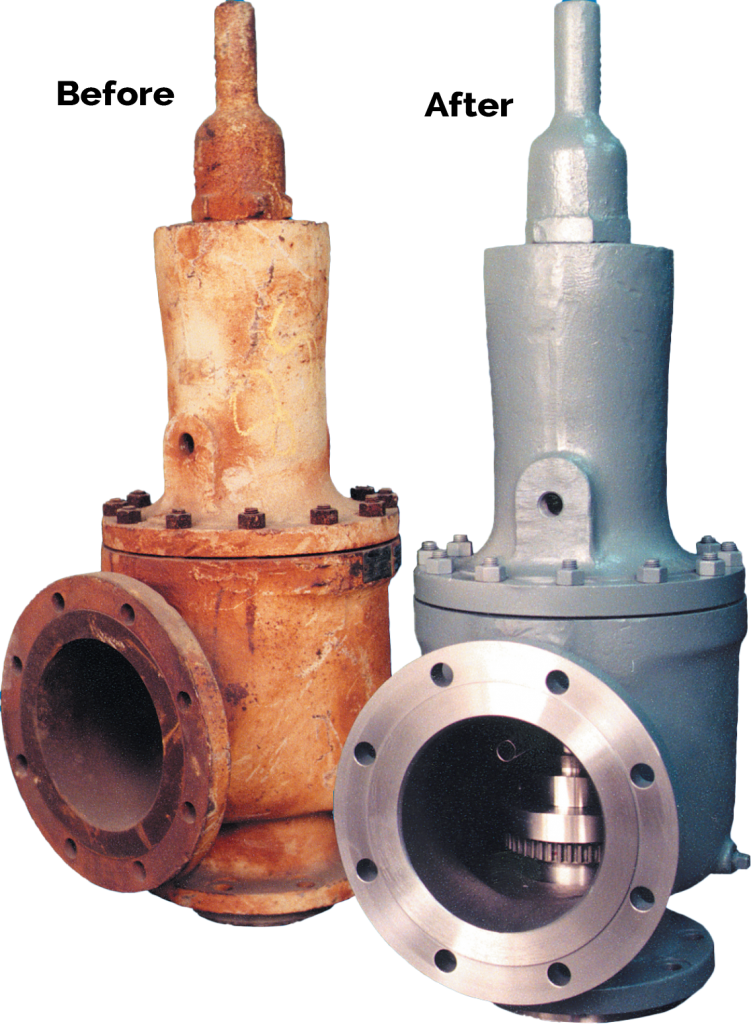

REMANUFACTURED VALVES

Choosing remanufactured safety and relief valves is a smart alternative for saving money and minimizing down time. It makes good sense for the majority of industrial uses because they are:

PARTS & REPAIR SERVICES

Contact us for more information or if you are ready to place an order.

|