Mueller Industries, Inc. is an industrial manufacturer that specializes in copper and copper alloy manufacturing while also producing goods made from aluminum, steel, and plastics. It is headquartered in Collierville, Tennessee and comprises a network of operations in North America, Europe, Asia, and the Middle East. Its products include tubing, fittings, valves, vessels, and similar items for plumbing and HVACR related piping systems, as well as rod, forgings, extrusions, and various components for OEM applications. Products are distributed into sectors such as building construction, appliance, defense, energy, and automotive.

Mueller Streamline Co. provides products supporting the plumbing, HVAC, refrigeration, PVF, and other markets. The company’s flagship products are Streamline® copper tubing, line sets, copper fittings, valves, and related items. Mueller Streamline Co. also provides Sales and Distribution support for other Mueller Industries brands, representing a wide assortment of flow control solutions.

Streamline® is the leading name in smart and efficient flow control solutions. With a full suite of products for plumbing, air conditioning, refrigeration, and other applications, Streamline® piping systems set the benchmark for reliability and confidence.

Mueller Streamline Co. provides products supporting the plumbing, HVAC, refrigeration, PVF, and other markets. The company’s flagship products are Streamline® copper tubing, line sets, copper fittings, valves, and related items. Mueller Streamline Co. also provides Sales and Distribution support for other Mueller Industries brands, representing a wide assortment of flow control solutions.

Streamline® is the leading name in smart and efficient flow control solutions. With a full suite of products for plumbing, air conditioning, refrigeration, and other applications, Streamline® piping systems set the benchmark for reliability and confidence.

|

|

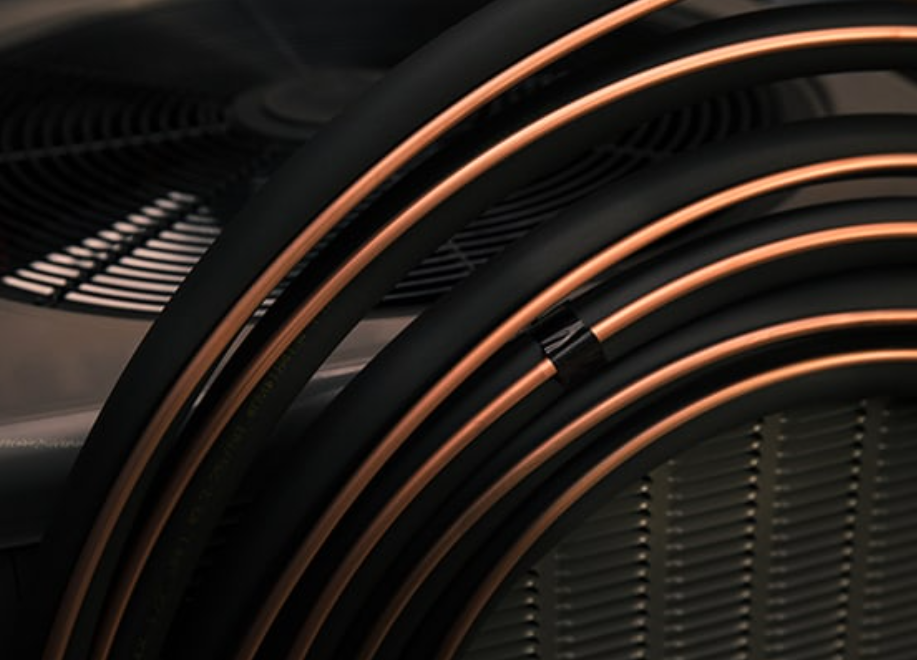

TUBE

Streamline sets the standard for quality and cleanliness in the HVACR and plumbing industries. With a full line of both copper and plastic-coated copper tube for plumbing, air-conditioning, refrigeration, medical gas and other applications, our copper tube products are the preferred brand of industry professionals. HVACR

PLUMBING

CO2 REFRIGERATION

MEDICAL GAS

SPECIALTY

Line Sets

Streamline® Line Sets have been an industry leader for decades. We leverage our many years of experience and expertise producing copper tube in every line set we make. From liquid line and suction line handling to unique insulation applications and packaging, every Streamline Line Set meets our rigorous standards for quality and consistency. With a broad offering of liquid line and suction line diameters, insulation, thickness, custom ends and connections – plus a wide array of custom options, we’re able to meet our customers most specialized and exacting needs.

Fittings

COPPER SOLDER JOINT Streamline® Wrot Copper Pressure and DWV fittings for use in plumbing or mechanical applications. Available sizes ranging from ¼” to 8” in diameter – Streamline® Wrot Copper fittings for use in refrigeration applications. Available sizes ranging from ¼” to 8-1/8” in outside diameter.

COPPER PRESS Streamline PRS™ mechanical press copper fittings are for use in plumbing or mechanical applications. Sizes range from 1/2″ — 4″ and the fittings are designed to join ASTM B88 (Types K, L, M) hard-drawn copper tube (1/2″ — 4″) and soft copper tube (1/2″ — 1-1/4″).

CARBON STEEL PRESS Streamline® Carbon Steel Press Fittings have been engineered with several unique features and industry firsts to provide unmatched joint integrity, optimum system flow, and installer ease of use. Fittings are manufactured to specific ASTM standards and applicable system demands, thoroughly tested, and third-party certified. Proprietary innovations make Streamline® Carbon Press Fittings the superior joining solution for your system:

COPPER-IRON Streamline® XHP™ Copper-Iron Fittings for use in refrigeration applications. Available sizes ranging from 3/8” to 2-1/8” in outside diameter for continuous 130 BAR / 1885 PSI pressure ratings at 120°C / 250°F.

PLASTIC Plastic fittings offered by Mueller Streamline Co. are designed and manufactured to the most exacting standards. With a fitting to meet most every common residential, commercial, industrial, irrigation and agricultural plumbing system application, our many lines of plastic fittings are simply the best in the industry. Each delivers excellent fit, smooth interior walls and outstanding corrosion and chemical resistance.

Contact us for more information or if you are ready to place an order.

|